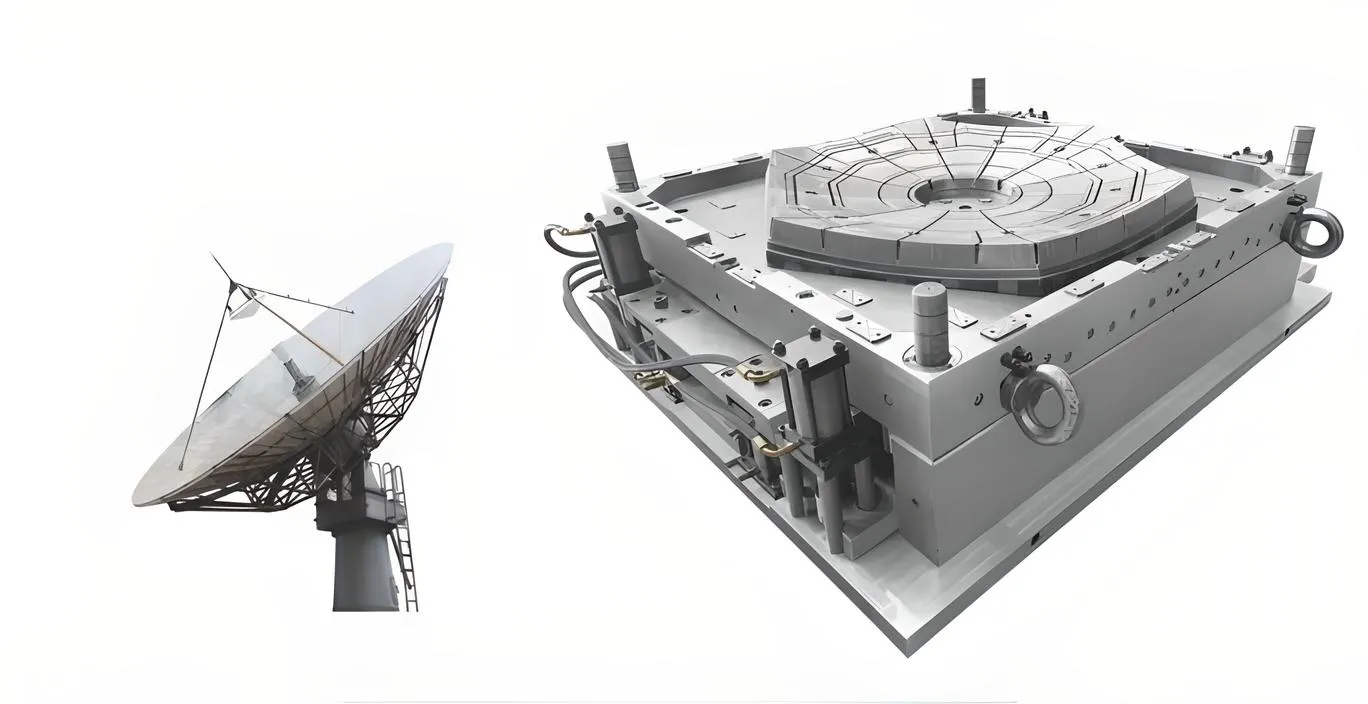

SMC Molding for FRP Antenna Molds: The Lightweight High-Frequency Solution for Satellite Communication

- Suase /

- SUASE NEWS

As satellite communication technology evolves, the demand for improved structural strength, signal accuracy, weight reduction, and environmental adaptability in antenna systems continues to grow. Utilizing Fiber Reinforced Plastic (FRP) and Sheet Molding Compound (SMC) materials through precision hot compression molding has become a key solution in manufacturing high-performance satellite antenna housings and reflectors, especially for high-frequency applications.

Advantages of FRP Antenna Molds

FRP antenna molds, manufactured using SMC as the raw material and shaped through high-temperature compression molding, offer distinct advantages over traditional metal tooling and fabrication methods:

- Lightweight Structure: SMC provides an exceptional strength-to-weight ratio, significantly reducing antenna mass and easing installation and deployment.

- Excellent Weather Resistance: Outstanding resistance to UV, salt spray, high and low temperatures ensures long-term outdoor durability.

- High Surface Smoothness: Ideal for producing accurate reflective surfaces essential for high-frequency wave transmission.

- Repeatable Mass Production: Molding consistency ensures each antenna component meets exacting dimensional and performance standards.

Lightweight Satellite Antenna Design Trends

In satellite systems, weight is a key factor affecting launch cost and structural design. While metals offer strength, they are dense and costly to machine. In contrast, SMC antenna molds allow production of lightweight satellite antennas that maintain structural integrity while supporting modular and compact system designs for modern communications.

Integration of Satellite Communication and High-Frequency Antenna Design

High-frequency communication requires antennas with precise dimensions, stable dielectric properties, and smooth surfaces. SMC molding achieves millimeter-level accuracy, minimizing distortion and ensuring signal clarity. SMC’s electromagnetic compatibility makes it ideal for antennas operating in K and Ka bands and other high-frequency applications.

Typical Application Fields

SMC-molded FRP antennas are widely used in:

- Ground satellite receiving stations

- Aerospace communication systems

- Shipborne satellite radomes

- 5G backhaul link antennas

- Military portable satellite terminals

Why Choose a Professional SMC Antenna Mold Manufacturer?

A professional SMC antenna mold supplier offers precision CNC machining, temperature-controlled compression molding, large-scale mold analysis expertise, and custom SMC formulation capabilities. Collaborating with an experienced partner shortens development cycles and ensures optimal performance in high-frequency antenna designs.

Conclusion

Considering performance, environmental resistance, cost, and production efficiency, manufacturing lightweight satellite antennas using SMC molding and FRP antenna molds is becoming the industry standard. As the deployment of high-frequency satellite communication networks accelerates, composite molded antennas will play a vital role in supporting global communication infrastructure with enhanced stability and efficiency.