Extensive Applications and Solutions of SMC Molds in the Automotive Industry

- Suase /

- SUASE NEWS

With the rapid development of new energy vehicles and lightweight design, SMC composite materials (Sheet Molding Compound) are playing an increasingly important role in the manufacturing of automotive parts. Suase (suasemould.com), as a professional SMC mold manufacturer, is committed to providing efficient, durable, and high-quality composite mold solutions for OEMs and component suppliers.

I. Typical Applications of SMC Molds in Automotive Structural Parts

SMC molds are widely used in automotive body structural parts, such as:

- Spare tire cover molds and spare tire well molds: One-step compression molding with excellent rigidity and lightweight performance.

- Battery tray molds and battery box upper cover molds: SMC materials offer flame retardancy, insulation, and high strength, making them ideal for EV battery compartment protection.

- Seat pan molds: Provide structural support while maintaining comfort and design flexibility.

- Underbody shield molds: Used for vehicle chassis protection, with impact resistance and thermal stability.

In high-strength, safety-critical components, SMC molds are gradually replacing traditional metal and plastic molds.

II. SMC Exterior Part Molds: Achieving High-Quality Class A Surfaces

For automotive exterior components, surface finish determines the product's value. The following molds developed by Suase are highly praised by customers:

- Fender molds, mudguard molds, and deflector molds: Achieve Class A surface quality with excellent weather resistance and aesthetics.

- Truck front mask molds and SMC front mask molds: Designed for large-size commercial vehicle exteriors, ensuring structural strength and efficient one-piece molding.

- Sun visor molds and SMC decorative panel molds: Suitable for vehicle interior parts, meeting lightweight and eco-friendly requirements.

These molds are widely used in various types of vehicles, including passenger cars, commercial vehicles, buses, and SUVs.

III. Structural Optimization of Functional Protective Part Molds

In a vehicle's safety protection system, structural molds are particularly critical:

- Bumper beam molds, bumper molds, and SMC bumper molds: Provide energy absorption structures and high impact resistance.

- Step shield molds and SMC footboard molds: Designed with anti-slip textures and ergonomic structures, widely used in commercial vehicles.

The reliability of these molds directly affects the overall safety and service life of the vehicle.

IV. Development Experience of Special-Purpose Molds

- Front-end module molds and roof side beam molds: Support multi-rib structure designs and precisely control molding deformation.

- Door inner panel molds: Meet demands for appearance, lightweight, waterproofing, and structural integration.

- Forklift shell molds and automotive leaf spring molds: Applied in industrial vehicles, requiring high strength and corrosion resistance.

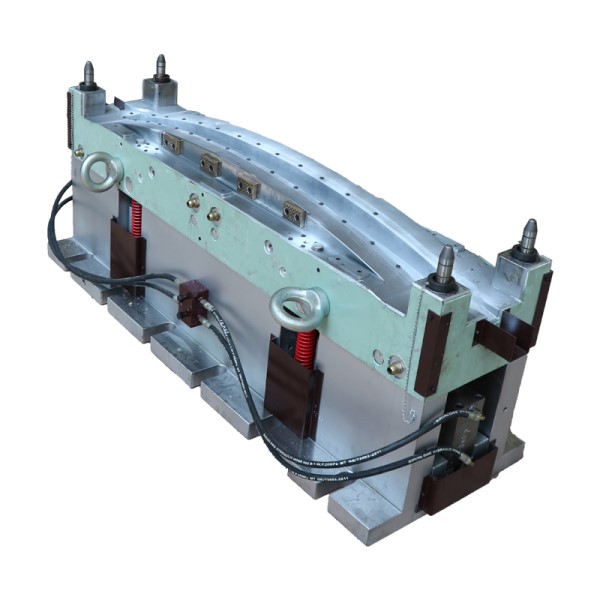

Suase has a variety of large-scale presses and extensive experience to quickly meet various composite mold needs.

V. Why Choose Suase as Your SMC Mold Supplier?

Suase (suasemould.com) focuses on the design and manufacturing of SMC molds, BMC molds, and composite material molds, with the following advantages:

- Extensive industry experience, familiar with the molding characteristics of various automotive exterior and structural parts.

- High-precision mold machining capability to ensure mold longevity and product quality.

- Fast prototyping and mass production delivery to meet customer lead time requirements.

- Support for customized mold development, flexibly adapting to multi-model design differences.

We have provided SMC mold solutions for many domestic and international OEMs and Tier 1 suppliers and continue to expand into new energy and industrial equipment composite applications.

Conclusion: SMC Molds – A Key Driver of Automotive Lightweighting

As the automotive industry moves toward electrification and lightweighting, SMC molds are becoming increasingly valuable. From bumper molds to battery tray molds, from truck front mask molds to forklift shell molds, Suase is committed to delivering efficient and reliable mold solutions for every client.

Visit our official website at www.suasemould.com to explore more products and case studies, or contact us for customized mold solutions.