As the new energy vehicle industry rapidly advances, battery system structural designs have become increasingly complex, demanding higher mold precision, material performance, and fabrication processes. This article, compiled by the Suase (SUASE.NET) technical team, thoroughly analyzes the critical roles and latest technological trends of battery enclosure tray molds and battery box upper cover molds in the NEV sector, helping industry professionals understand composite mold solutions in depth.

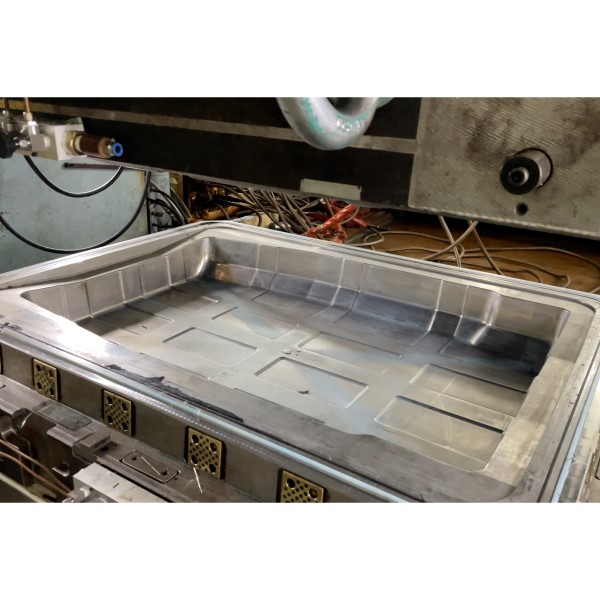

Battery Enclosure Tray Molds: The Foundation of Load-Bearing Structure and Thermal Management

Battery enclosure trays are typically manufactured from SMC (Sheet Molding Compound) or carbon fiber–reinforced composites, offering light weight, high rigidity, and corrosion resistance. Tray molds must not only achieve tight dimensional tolerances but also address strength, heat dissipation, fire protection, and integration requirements.

1. Functional Characteristics

- High load-bearing capacity to secure battery modules

- Integrated cooling channels for rapid heat removal

- Lightweight yet strong design using SMC/BMC materials

- Flame retardant and corrosion resistant for enhanced safety

2. Mold Design Considerations

- Multi-cavity split lines and precise insert positioning

- Optimized hot runner and mold temperature control systems

- Enhanced demolding structure for higher production efficiency

Battery Box Upper Cover Molds: Key to Structural Sealing and Safety Protection

Battery box upper covers protect batteries from impacts and environmental corrosion and are also made from high-strength, electrically insulating SMC/BMC composites. Cover molds must balance lightweight design, safety features, and production throughput.

1. Technical Requirements

- Complex geometry requiring high-precision CNC machining molds

- Material diversity: SMC, carbon fiber, and thermoset composites

- Compliance with UL94 V0 flame-retardant standards

- Tight sealing and high assembly accuracy

2. Manufacturing Focus

- Selecting wear-resistant mold steels

- Clear parting lines and optimized draft angles

- High-level surface finishes to prevent cosmetic defects

Materials & Forming Processes: How Composites Drive Mold Technology Innovation

1. SMC Compression Molding

Offers high strength, heat resistance, and flame retardancy, making it a mainstream material for trays and covers.

2. BMC Molding

Ideal for smaller battery components due to superior flow for complex detail molding.

3. Carbon Fiber Composites

Used in high-end EVs with RTM and vacuum infusion processes, requiring even higher mold sealing and precision.

Core Capabilities of Mold Manufacturing Companies

- High-end equipment: 5-axis CNC, mirror EDM, etc.

- Comprehensive mold flow analysis and CAE simulation

- Integrated mold temperature control and ejection systems

- Deep understanding of battery pack structures for collaborative development

Typical NEV Industry Case Studies

Suase has supplied both tray and cover molds to numerous OEMs and Tier 1 battery suppliers, including:

- High-performance SMC tray molds for leading domestic EV brands

- BMC upper cover molds exported to Europe, meeting stringent EU standards

- Composite mold solutions with integrated water cooling and wiring harness channels

Future Trends in the Industry

- Smart molds with real-time sensor monitoring and predictive maintenance

- Green manufacturing: rapid development of recyclable composite materials

- Integrated designs: one-shot molding of entire battery enclosures

- Co-development: simultaneous mold and battery pack design workflows

About Suase (SUASE.NET)

Suase focuses on composite mold R&D for NEVs, offering tray molds, cover molds, SMC/BMC molds, carbon fiber molds, and compression molds. We provide one-stop solutions from design to trial. For more information, visit www.suase.net.