Suase Unveils Cutting-Edge EV Battery Enclosure Using Compression Molding

- Suase /

- SUASE NEWS

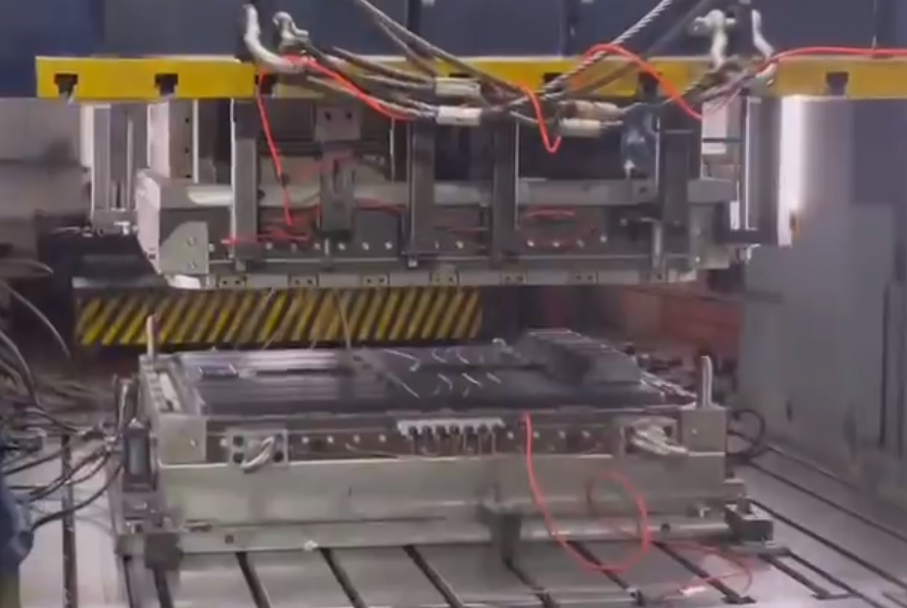

In a remarkable leap forward in electric vehicle (EV) technology, Suase has proudly introduced a state-of-the-art EV Battery Enclosure, manufactured through precision Compression Molding. This innovative development marks a significant milestone in the realm of composite materials and advanced manufacturing techniques.

Key Features of the EV Battery Enclosure:

Composite Brilliance: The EV Battery Enclosure stands out as a masterpiece of composite engineering. Leveraging advanced materials, particularly Fiber-Reinforced Polymer (FRP), the enclosure exhibits unparalleled strength, durability, and lightweight characteristics. This composite brilliance ensures optimal performance and safety in the challenging automotive environment.

Precision through Compression: Suase's utilization of Compression Molding technology sets a new standard in the production of EV battery enclosures. This method involves the application of pressure and heat to mold the FRP composite materials into the desired shape, resulting in a precisely crafted enclosure that meets the stringent requirements of the electric vehicle industry.

Enhanced Structural Integrity: The compression molding process employed by Suase enhances the structural integrity of the EV Battery Enclosure. The resulting product demonstrates remarkable resistance to external forces, ensuring the safety of the battery and contributing to the overall robustness of the electric vehicle.

Tags for Discussion: #Composite #Compression #FRP

Composite Advancements: The incorporation of FRP in the EV Battery Enclosure reflects the ongoing advancements in composite materials. The workshop's commitment to composite excellence aligns with the industry's pursuit of lightweight and high-strength solutions for electric vehicles.

Compression Molding Innovation: The use of compression molding showcases Suase's commitment to adopting cutting-edge manufacturing techniques. This innovative approach not only streamlines the production process but also contributes to the precision and consistency of the final product.

FRP Technology in Electric Vehicles: As electric vehicles continue to gain prominence, the role of FRP technology becomes increasingly crucial. The EV Battery Enclosure by Suase exemplifies the integration of FRP in achieving optimal performance, safety, and sustainability in the electric mobility sector.

Suase: A Trailblazer in Composite Manufacturing

Suase's unveiling of the EV Battery Enclosure reinforces its position as a trailblazer in composite manufacturing. The workshop's dedication to pushing the boundaries of technology and its commitment to sustainable solutions make it a noteworthy player in the rapidly evolving landscape of electric mobility.

In conclusion, the Suase's display of the EV Battery Enclosure by means of Compression Molding underscores a transformative moment in the electric vehicle industry. This breakthrough not only showcases the workshop's technical prowess but also sets a precedent for the future of composite materials in electric vehicle applications.