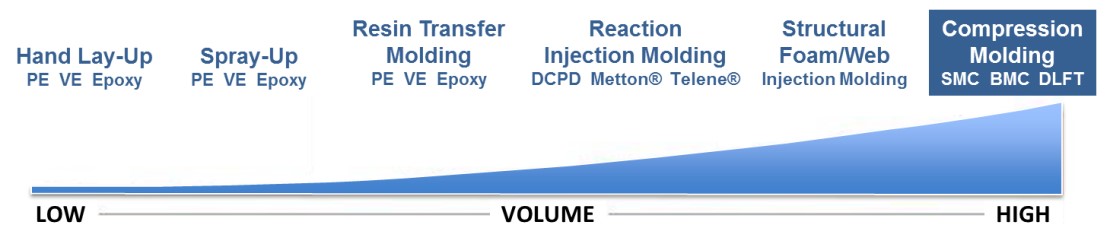

Compression tooling plays a crucial role in modern manufacturing processes, particularly in the production of high-strength and durable parts. Let’s delve into the details of compression tooling, its applications, and its significance.

Understanding Compression Molding

Compression molding is a molding technique that transforms plastics, natural rubbers, composites, and elastomers into desired shapes. The process involves placing the material in a mold cavity and then compressing both mold halves. Here’s how it works:

- The mold cavity and feed material are pre-heated.

- Heat and pressure cause the material to flow into every intricate detail of the mold.

- After cooling and solidification, the material takes on the desired shape.

Compression molding is versatile and compatible with various part thicknesses, sizes, and complexities. It is widely used across industries, from automotive and aerospace to kitchenware.

Types of Compression Molds

Compression molds come in three main categories:

- Flash Molds: These molds do not require accurate feeding. Excessive material is shaped, and any excess escapes during compression. Flash molding is cost-effective for molding cheaper raw materials and can produce complex shapes.

- Positive Molds: In positive molds, accurate feed amounts are used, resulting in zero material waste. These molds are ideal for expensive raw materials and are preferable for deep-depth designs.

- Semi-Positive Molds: These molds fall between flash and positive molds in terms of accuracy.

Applications and Advantages

Compression molding offers several advantages:

- Low defects and high-strength precise parts

- Dimensionally consistent parts regardless of production volume

- Cost-efficient for large-volume production

- Used in automotive, aerospace, and other industries

Whether you’re shaping thermoset materials or creating intricate components, compression tooling is a fundamental part of the manufacturing landscape.